There are 4 main adhesive applicators. Which is best for you?

The wide world of adhesives includes a galaxy of types from acrylics to urethane, vinyl acetate and epoxy resins. Application methods are also diverse, including hand brushing, hand rolling and cartridge guns as well as automatic spray guns, dispensers and roll coaters. Deciding on the best one for your needs can be difficult. If you read this article, you will find out the characteristics of each automatic applicator and things will become much clearer.

“There are so many adhesive applicators that I can’t possibly choose”

What types of automatic adhesive applicators are there? In general terms there are automatic spray guns, dispensers, roll coaters, curtain coaters, dip coaters…and more. Then, within the category of roll coaters, for example, there are about 10–20 types, such as reverse roll coaters, gravure coaters, die coaters and bar coaters. The more you look, the greater the sense of overwhelming futility.

So, by what standard should you select an application method? First, you should check three things: 1) the type and viscosity of the adhesive, 2) the size and shape of the target object (substrate) and 3) your budget.

To narrow down your options, consider the viscosity of the adhesive, the form of the target object and your budget

1) The type and viscosity of the adhesive

Among applicators, some types can handle highly viscous adhesives, and some cannot. If you are using a highly viscous adhesive fluid of over 10,000 mPa⋅s (millipascals per second), you are limited in the devices available. Once you move into the ultra-viscous adhesives of 100,000 mPa⋅s or more, very few dispensers will be able to do the job. Moreover, if you are using a hot-melt process to spray your adhesive, you will need a machine that can handle this.

2) The size and shape of the target object

Is the target object (substrate) three-dimensional, curved or flat? If it is a film, a roll coater would be a good choice. On the other hand, if it is not flat, you cannot use a roll coater.

3) Your budget

If, as in the production of sticky tape or labels, the application of adhesive represents a major part of your manufacturing process, it would be more efficient to install a highly productive large machine, even if it costs hundreds of thousands of dollars. On the other hand, if applying adhesive is just a small part of your overall process, you would typically choose an automatic spray gun or a dispenser that is cheaper than such a machine and takes up less space.

In addition to the three conditions above, you can narrow down the list of suitable devices if you consider aspects such as the thickness of application you are looking for.

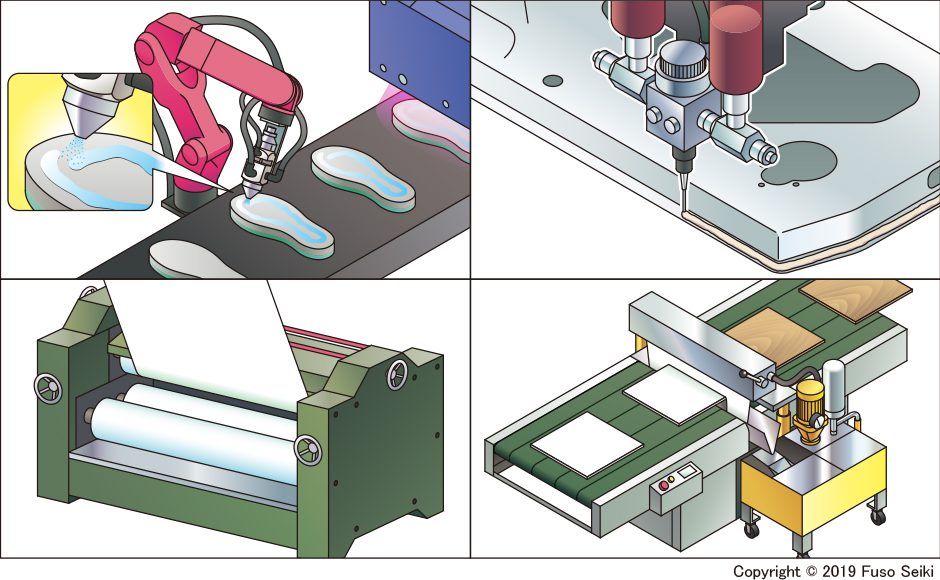

Now, let’s look at the characteristics of the major applicators. Here we will focus on four: automatic spray guns, dispensers, roll coaters and curtain coaters.

The spray gun is the standard for applying adhesive

Spray guns are the most versatile of adhesive applicators. Able to handle a diversity of work scales and forms, they can apply adhesive to wide target objects or with pinpoint accuracy. They are often used in the manufacture of furniture, shoes and car interior furnishings.

They are not designed for highly viscous adhesives, which can clog them up. As a rule of thumb, they work for adhesives of around 5,000 mPa⋅s. They can handle textures like condensed milk, ketchup and shampoo, but may start to gum up at around the viscosity of honey (10,000 mPa⋅s). (Whether or not you can stably apply the adhesive also depends on its liquid characteristics). The cost of a spray gun is low, ranging from hundreds of dollars to two thousand dollars.

Ultra-viscous adhesive handling dispenser

An application device that pushes out the liquid with pressure. Applies adhesive in dots and lines. It is a highly accurate way of applying small quantities of viscous fluid and used in the manufacture of consumer electronics, integrated-circuit chip sealing and packaging.

Handles highly viscous adhesive, however, its weaknesses are the inability to apply widely, or in an upward or sideways direction. Prices vary widely from around a thousand dollars per unit up into the hundreds of thousands.

The roll coater, a specialized device for applying to paper and film

A large machine for continuous application. Applies adhesive using a paint roll or blade to the material feeding into the machine, such as flat objects like paper and film. There are 10–20 subtypes depending on the application mechanism and structure, such as the reverse roll coater, knife coater, kiss coater and gravure coater.

The best one for your needs will depend on the viscosity and thickness of the adhesive. As a large unit, most such devices will cost more than a hundred thousand dollars. The slot-die coater, which is capable of precise application, is extremely expensive.

Curtain coaters create an immersive “waterfall” of adhesive

A method whereby the adhesive falls vertically down onto the substrate to coat it. It is mainly used to apply to paneling and other flat materials, but unlike a roll coater, it is also useful for relatively uneven materials. However, it can only be used to apply fairly low viscosity fluids.

Apart from the above, there are applicators like the dip coater which we are not presented here. At any rate, there are a lot of types of devices for applying adhesives, but around 2 or 3 that are frequently used for each kind of object. By working out the adhesive viscosity and thickness you need – and your budget – you will find the right device.

Note: Prices for each device are general estimates. The actual price will vary according to the functions, size and options included.