Others

Example 1

- User

- Electronics manufacturer

- Application

- Spray fluxing

- Model used

- STS-10SK-0.5X-MHS

Problem

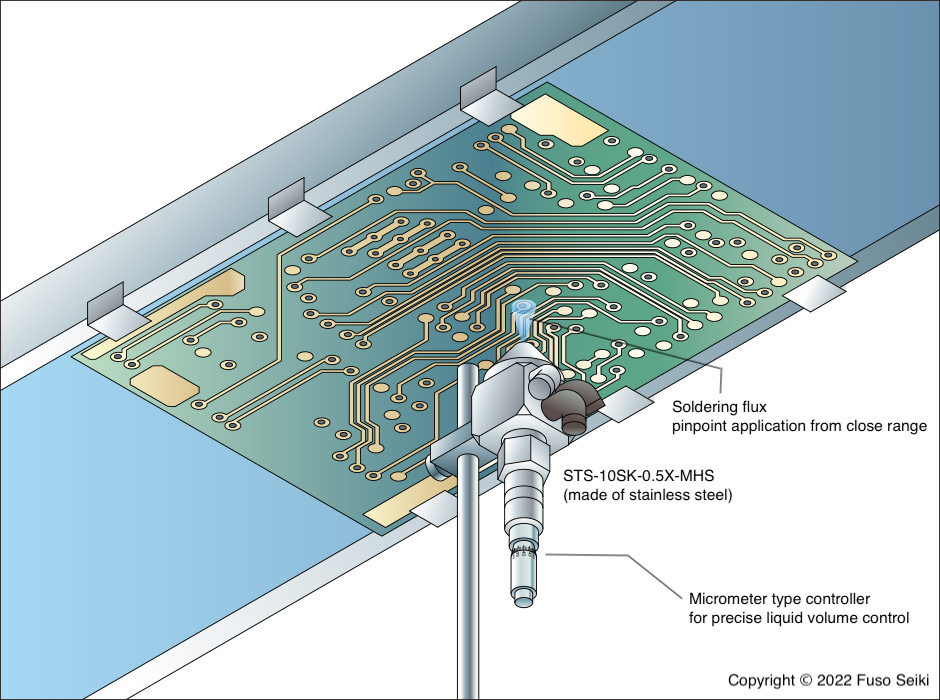

This electronics manufacturer makes printed circuit boards in-house for use in its products. Prior to the soldering process, the boards must be fluxed and the oxide film at the joints removed. They looked for a way to apply flux with pinpoint accuracy only to the through holes.

Lumina’s proposal and result

Pinpoint application with a 10 mm diameter is possible with an ultra-fine round spray pattern (SK type) model. The STS-10SK-0.5X-MHS is made of stainless steel to accommodate corrosive fluxes. It is equipped with a micrometer liquid volume adjuster that allows fine adjustments and at-a-glance grasp of the liquid volume setting.

- (Spraying conditions)

-

- Atomizing air pressure: 0.1 MPa

- Liquid pressure: 0.05 MPa

- Target distance: 20 mm

The spray distance was set at 20 mm to make the spray pattern as small as possible. We were able to apply flux only to the through holes by spraying while moving the board in a programmed manner.