Common Problems & Fixes – My Spray Gun is not Spraying Properly! Common Causes and Solutions

In our Common Problem & Fixes series we explain the cause and provide solutions to the various product challenges and questions we receive from our customers. In this column we address the problem of the spray gun not spraying liquid properly.

6 Main Reasons Why the Sprayer does not work

We sometimes receive questions from our customers about why their spray guns have stopped spraying liquid properly such as, “I put everything together according to the manual, but the gun won’t spray!” or “The gun was working fine last week, but it suddenly stopped spraying.” We have put together the six most common causes below.

Insufficient piston-actuating air

The liquid adjuster is not opened sufficiently

The valve is not opened on the liquid tank

The liquid is not reaching the spray gun

Debris is stuck in the liquid line

Insufficient grease on the piston set

You just purchased an automatic spray gun and connected the lines according to the manual. If it does not spray properly, please review the first four points. We will explain them each in further detail.

Insufficient piston-actuating air

As described in our article, “Structure and Use of Automatic Spray Guns,” automatic spray guns use air pressure to control the start and stop of spraying. Applying approximately 0.2 to 0.3 MPa (varies by device) of air pressure to the piston set will open the liquid line. If insufficient air pressure reaches the piston, however, no liquid will come out (Only air will spray out from the tip).

If your spray gun was working just fine previously, you might think it must have enough air pressure. Even so, you might have made a mistake connecting the tubes after detaching the spray gun for cleaning. The piston requires 0.2 to 0.3 MPa of air pressure for actuation, but the atomizing air line typically only provides 0.02 to 0.15 MPa of pressure. If you connected the tubes incorrectly, the spray gun will not spray.

Furthermore, if you attach multiple devices to a single air supply, the pressure might only be insufficient when those other devices are in use and drawing air pressure. To check if the piston set is functioning properly, please place your finger on the liquid adjuster. When the piston set is working properly, you will feel a vibration in the adjuster when the piston is open. If you do not feel the “click-click” of the piston set, it may not be working properly.

The liquid adjuster is not opened sufficiently

Please rotate the liquid adjuster 2–3 times to sufficiently release the spray (ST-6 series: 2 times, ST-10 series: 3 times). The spray gun is designed to not release liquid for the first 1–2 rotations of the liquid adjuster (the rotations required to release liquid vary by model). Open the air valve and once the device has begun spraying adjust the liquid flow using the adjuster.

The valve is not opened on the liquid tank

One simple mistake is to leave the valve for the liquid supply tank closed. Please double-check whether the valve is open.

The liquid is not reaching the spray gun

Confirm the liquid is travelling all the way to the spray gun. If the liquid is highly viscous or the tube is too long, the liquid flow may stop without reaching the spray gun. When this occurs, you can either use a wider tube for the liquid line or shorten the total line length. Also avoid placing the tube on an upward angle to the greatest extent possible.

Splitting the liquid tube will also cause a drop in pressure. Attaching too many spray guns to a single source liquid line can cause the liquid to stop in the tube. Multiple liquid supply tanks are sometimes required if you will operate multiple spray guns. Using transparent liquid tubes makes it easy to identify when the liquid has stopped in the tube.

Common Mistakes during Cleaning

The following two problems can occur when you operate the spray gun continuously for a long period of time.

Debris is stuck in the liquid line

Debris, such as solidified particles from the spray liquid, can accumulate inside the spray gun and cause patchy or blocked spraying.

Blockages occur most frequently at the tip of the spray gun (the air cap and liquid outlet). If the air cap is blocked, please clean it using rag wet with paint thinner or cleaning fluid (Please see the article “What to do if Your Spray Gun Clogs” for more details). Please clean the spray gun if debris has accumulated on the liquid outlet or inside of the spray gun (download the maintenance manual here).

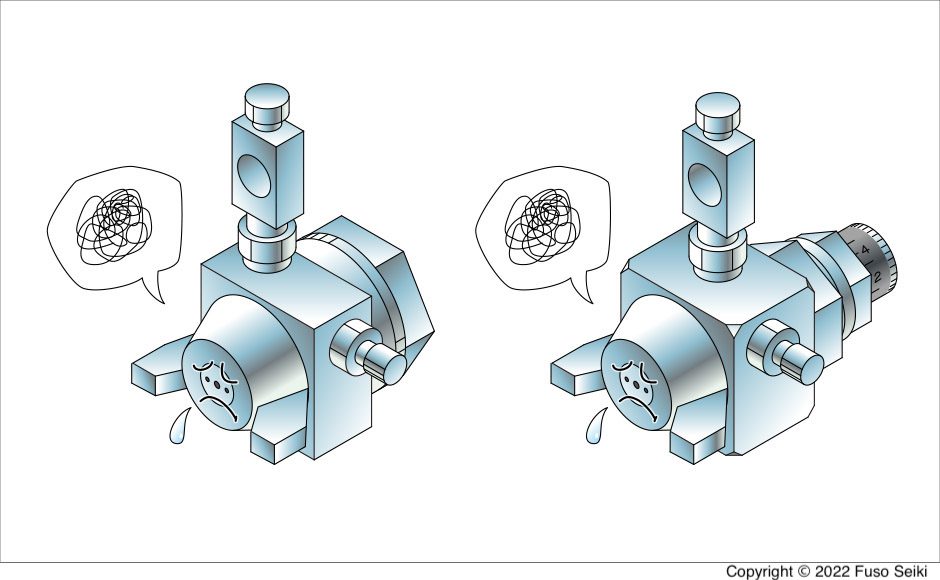

Insufficient grease on the piston set

Make sure you grease the piston set after taking apart and cleaning the spray gun. Without grease, the piston set will start moving poorly as you open and close the valve repeatedly.

The spray gun contains a chamber that allows the piston set to move forwards and backwards. The piston chamber is closed externally and the O-ring on the piston provides sealing.

The O-ring is coated with grease to ensure the piston chamber remains sealed and allow the piston to retract smoothly when air pressure enters the chamber. If the grease is removed during cleaning, however, the O-ring will have too much friction and prevent the piston set from retracting properly. That is why you should always apply new grease to the O-ring after cleaning.

The O-ring is made from nitrile rubber (NBR), which means it will swell if it contacts organic solvents. Be sure to remove the O-ring when cleaning the spray gun, and ensure it does not come in contact with paint thinner or cleaning fluids (the spray gun is designed to ensure the O-ring should almost never come in contact with liquids during normal use, so it should not swell from use). If the O-ring is degraded, please replace it with a new O-ring that is properly greased. This should restore the normal function of the spray gun (download the maintenance manual here).

We’ve explained the six common causes of your spray gun not spraying liquid properly. Please contact us if you still have trouble after checking these causes. We will carefully inquire on the state of your spray gun to help you return it to normal function.